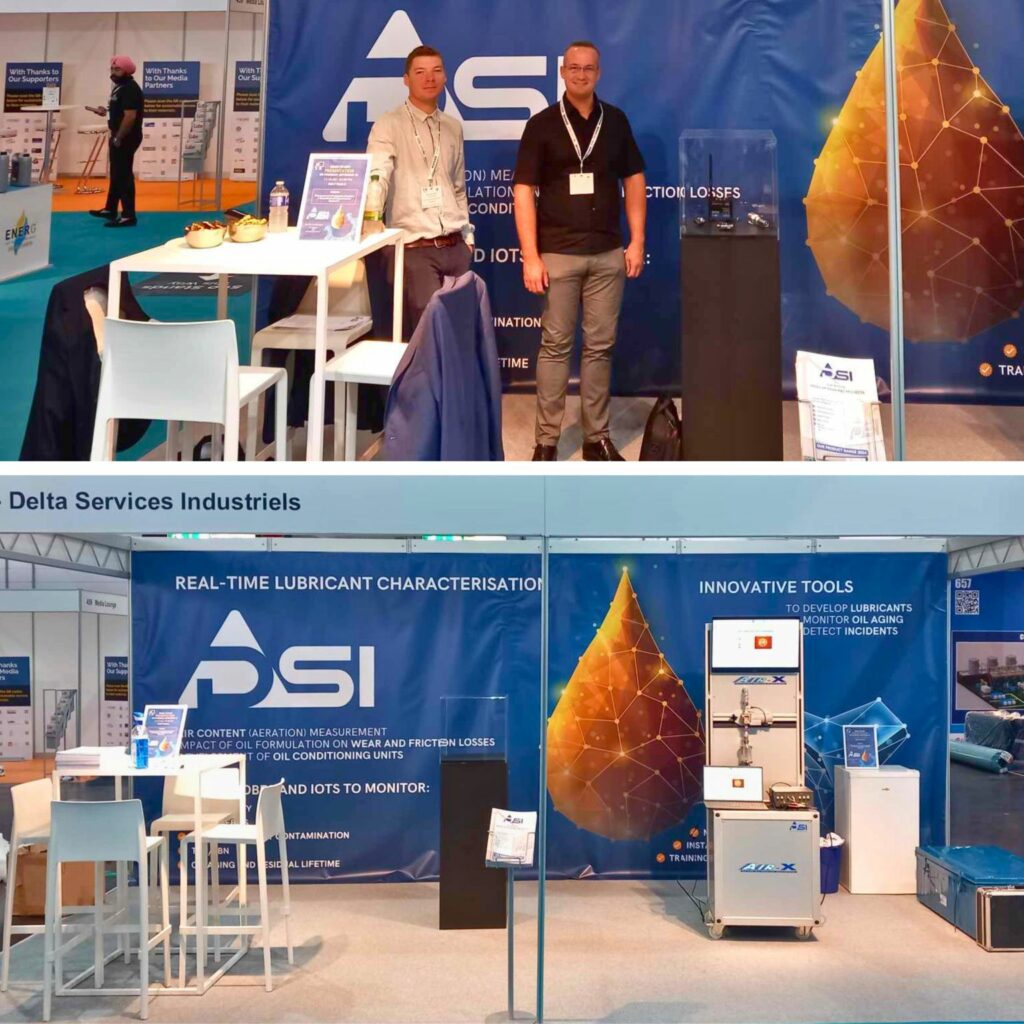

LUBRICANT EXPO GERMANY

Come and visit DSi – Delta Services Industriels at Lubricant Expo Düsseldorf (Germany) on September 17th – 19th, 2024.Our team is present on Stand 553. Thierry Delvigne will make an interesting presentation on Thursday, September 18 – 11:15 am to 01:00 pm – Hall 9, Track 2Subject: Measurement of Lubricant Aeration : A Theoretical and […]

LUBRICANT EXPO GERMANY Read More »

FLUCOIL, FLUID CONDITIONING UNIT FOR ACCELERATED OIL AGING

The innovative tool to accelerate lubricant aging and investigate their change of properties. FLUCOIL is designed to study the changes of lubricant properties during their lifetime. This innovative test rig also allows comparing lubricant formulations while speeding-up the aging process. The equipment can be programmed to simulate lubricant conditions in real mechanical systems such as

FLUCOIL, FLUID CONDITIONING UNIT FOR ACCELERATED OIL AGING Read More »

AIR-X, THE RIGHT TOOL TO MEASURE AIR IN OIL

➡ Air-X equipment is designed for real-time measurement of lubricant aeration within running mechanical systems: I.C. engines, e-powertrains, transmissions, compressors and any industrial equipment equipped with a lubrication system. ➡ The operating principle is based on an accurate density measurement using X-ray transmission. ✔ DSi team has acquired a strong expertise in assisting engineers to

AIR-X, THE RIGHT TOOL TO MEASURE AIR IN OIL Read More »

PRECISE QUANTIFICATION OF OIL CONTENT IN AIRSTREAMS

✔ The methodology is dedicated to R&D centers involved with the development of compressors, oil separators and any other system where the presence of oil in airstreams must be banished.Oil-in-air can be the cause of oil consumption on mechanical systems such as internal combustion engines or compressors. ✔ B-Lube offers significant advantages over other methods:➡ On-line

PRECISE QUANTIFICATION OF OIL CONTENT IN AIRSTREAMS Read More »

SPEED UP THE DEVELOPMENT OF YOUR LUBRICANTS AND ADDITIVES

DSI offers equipment and test services to accelerate the development of lubricants Our expertise covers the following topics: – Impact of formulations on wear and aeration– Impact of alternative fuels on lubricant aging– Test of lubricants in real operating conditions– Solutions for real-time measurement of lubricant degradation, presence of wear debris, change of viscosity, presence

SPEED UP THE DEVELOPMENT OF YOUR LUBRICANTS AND ADDITIVES Read More »

CONVERSION OF TEST CELLS FOR THE DEVELOPMENT OF HYDROGEN COMBUSTION ENGINES

DSi develops solutions for implementing hydrogen distribution equipment in test cells for ICE (Internal Combustion Engines). Our services cover all steps for converting conventional fuel distribution systems to hydrogen, including safety issues: • Pre-study: analysis of your existing test equipment and proposal for implementing a cost-effective solution• Risk analysis• Engineering: selection and implementation of all

CONVERSION OF TEST CELLS FOR THE DEVELOPMENT OF HYDROGEN COMBUSTION ENGINES Read More »