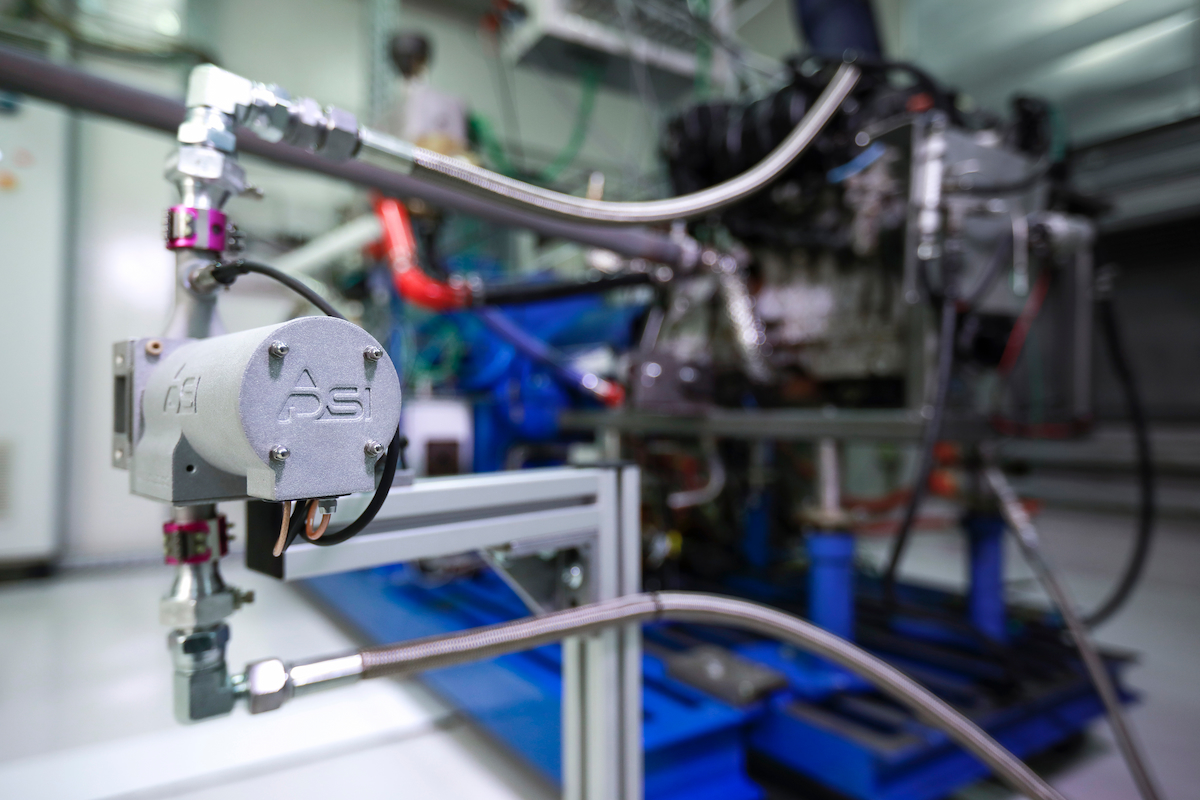

Air-X

Oil Aeration Measurement

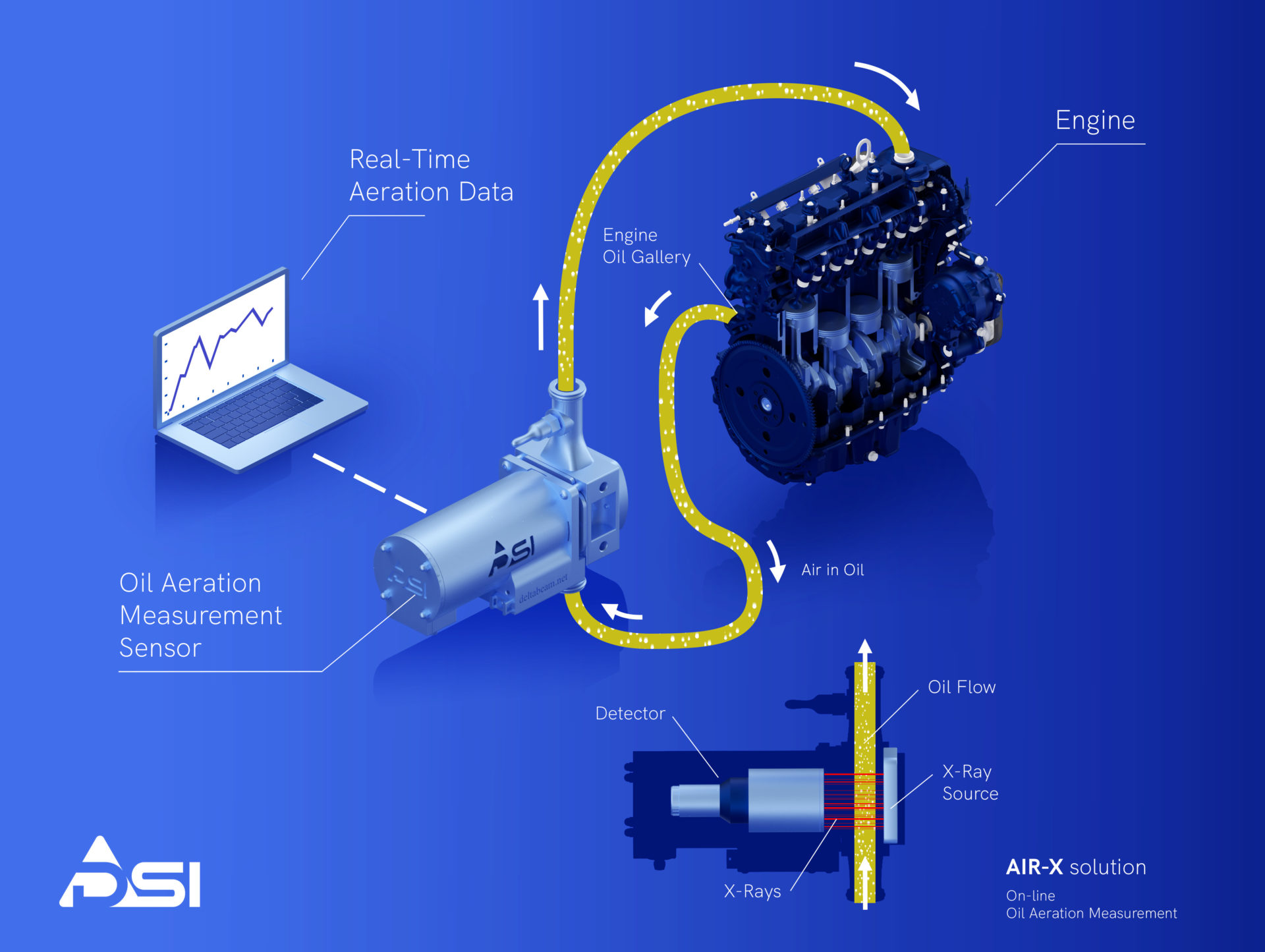

Air-X measures oil aeration in real time.

Field of Application

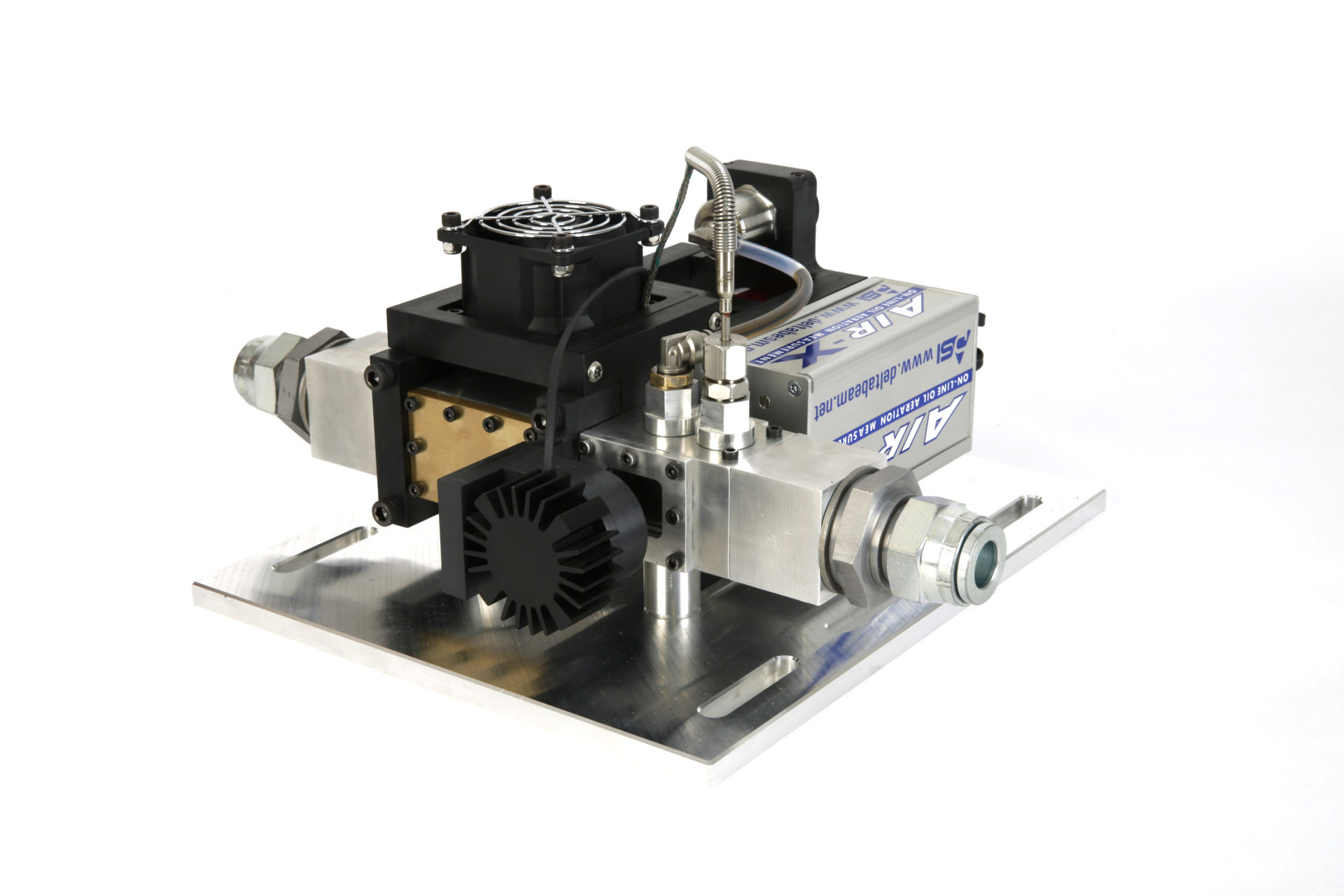

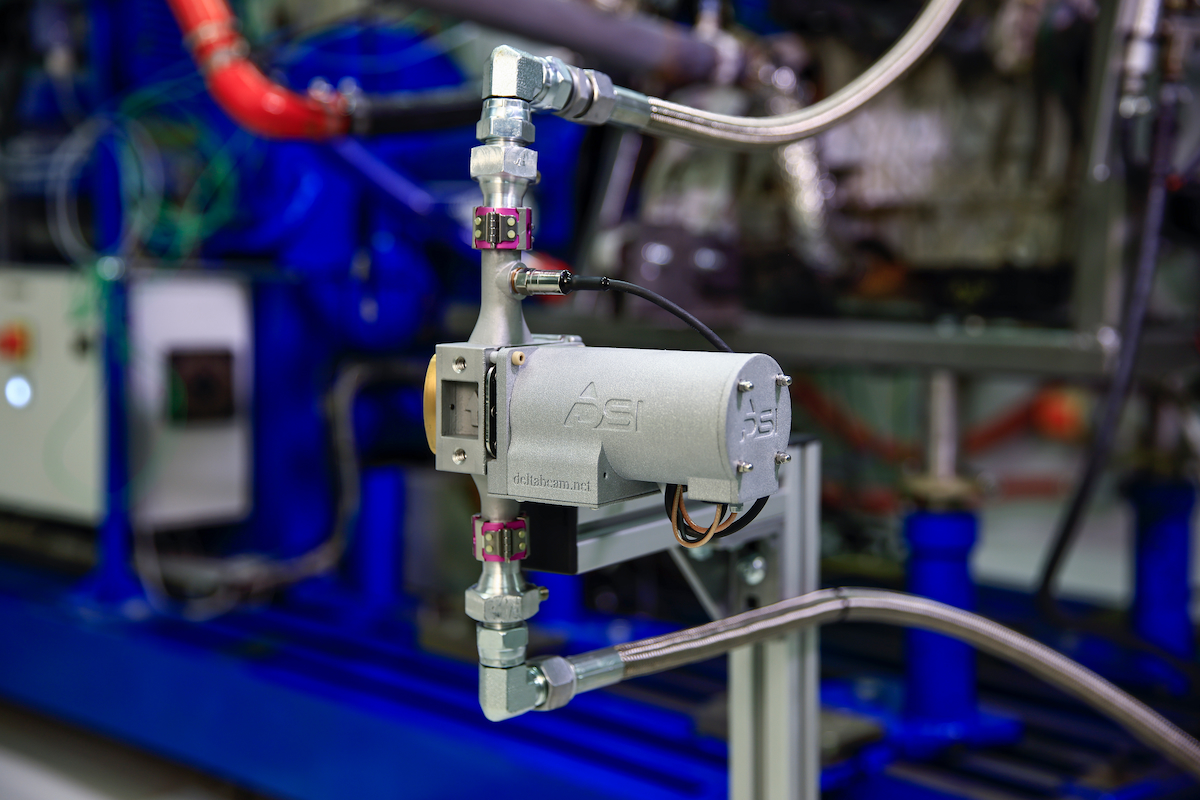

Air-X is an instrument designed for on-line monitoring of oil aeration in a running mechanical system. The operating principle is based on an accurate density measurement using X-ray transmission. An oil sample coming from the mechanical system is circulated continuously into a compact measuring chamber where the density measurement is performed.

Applicable on all fluids, our equipment, originally applied on engines, can be used in a lot of applications.

Combine it with Air-Mix to generate controlled aeration and measure it.

Medical : read case study

Measurement Performances

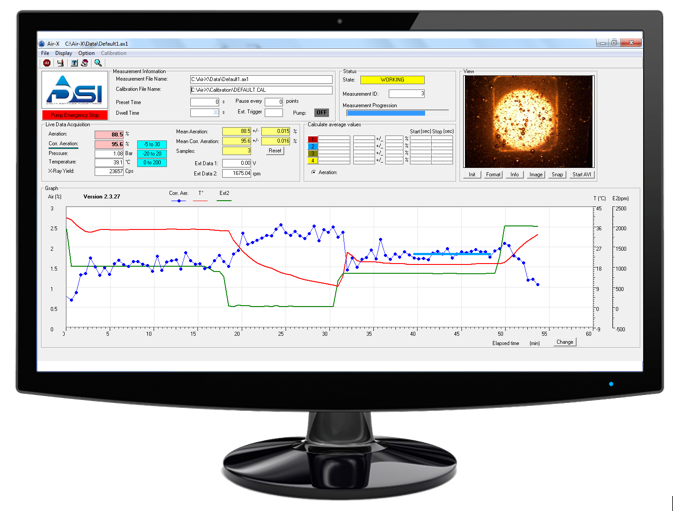

Real time aeration monitoring from 0% to 100%

Accuracy 0.5% at 10 sec and 0.2% at 100 sec

Oil or fluid flow variable from 0,5 to 5 liters/min

T° range : -10°C to 160°C

Custom Made Possibilities

Air-X exists under different versions : standard, compact and super compact.

Possible to buy or rent (weekly, monthly, yearly)

User-friendly set-up : autonomous just after 1 day training, simple interface with logical functions, maintenance only every 2 years

Tests can be performed in our DSi test centre or in your own facilities

Combine it with an Air-Mix to generate and measure oil controlled aeration

Useful for Eclectic Fields

Automotive

Racing

Mobility (railroad & trucks)

Production line

Medical

Offshore oil industry

Naval

Worldwide References

60 Air-X sold worldwide in 30+ countries

75% of all engine manufacturers have already used Air-X

100% of all Formula One engines manufacturers use Air-X