Smart probes for lubricants

DSI offers complete solutions to migrate from off-line oil analysis to real-time monitoring

Field of Application

Any industrial equipment filled with oil (wind turbines, power generators, transmissions, engines for off-road vehicles, etc).

Assistance to select the appropriate(s) probe(s) for measurement of viscosity, dielectric constant, content in wear debris, fuel and water content, TAN-TBN,...)

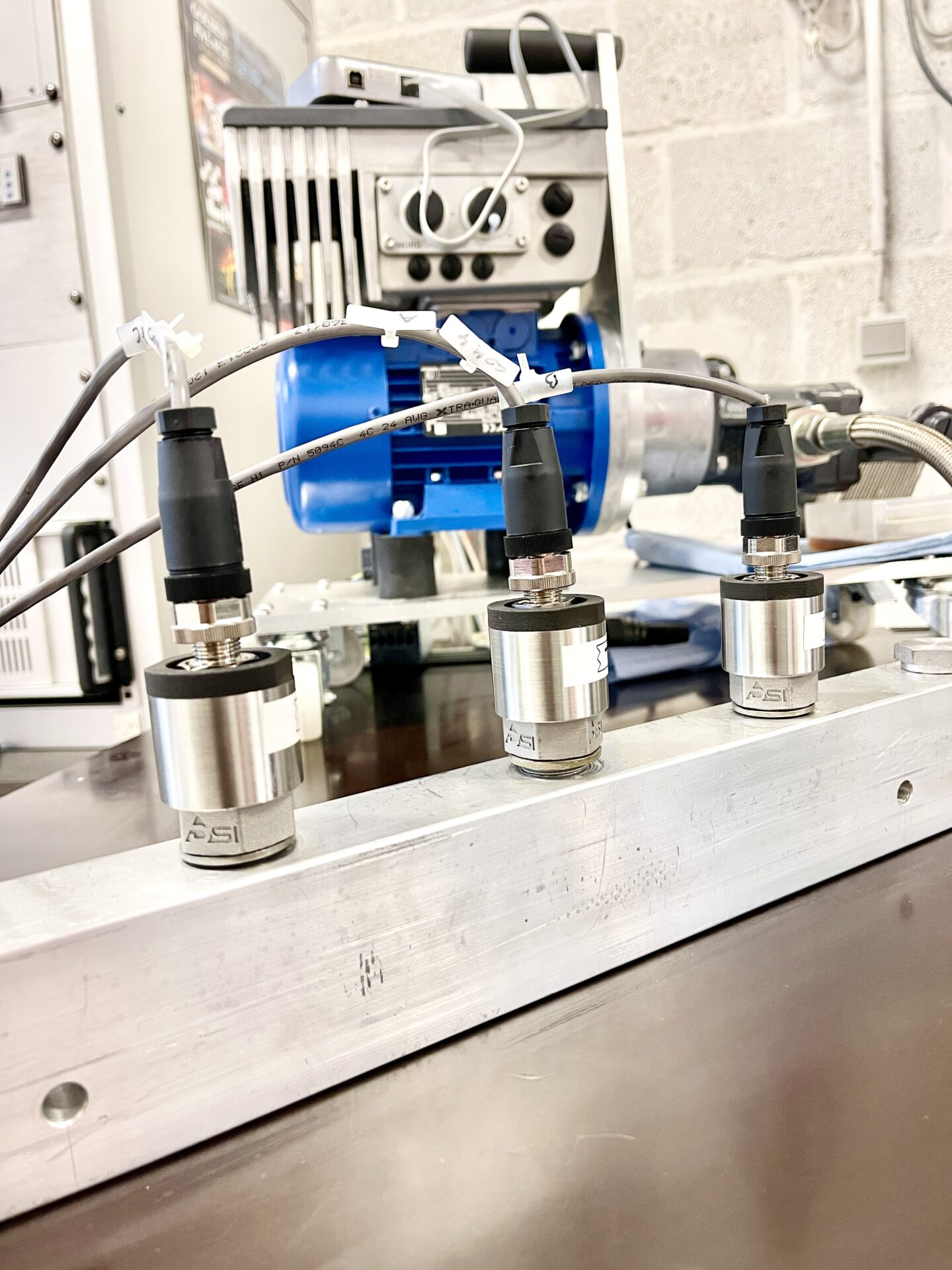

Design and manufacturing of hydraulic interfaces

Installation of probes and gateways

Data saving and real-time analysis tools

Development of HMIs

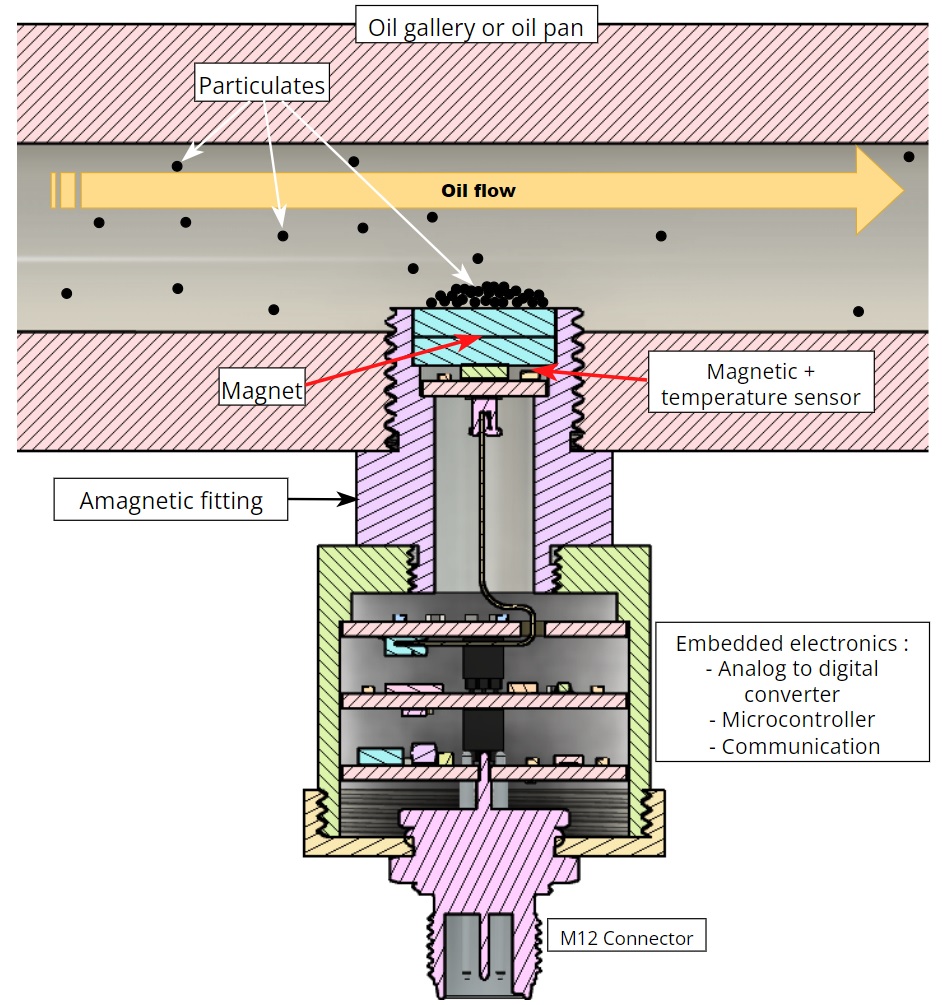

DSI probe detecting ferromagnetic particles down to 1 micron

Expertise and after sales services

Typical parameters of smart probes for lubricants

Viscosity

Water content

Wear contamination

Aeration level

Oil aging

Temperature, pressure and oil level

Machinery Health Assessment Software

Supervise health of industrial equipment

Information coming from each probe is collected, saved, and analyzed in real-time.

Dedicated algorithms allow forecasting maintenance programs

Immediate response when an accident occurs

Predictive maintenance programs with oil changes

Benefits

No more periodic sampling

Spare 3-5 days delay to get your analysis

Real time detection of oil quality and incident

Predict exact timing for oil change

Reduced maintenance cost

Components test

Gearboxes and transmissions

Engines and E-Powertrains

Power generators

Wind turbines

Any Hydraulic systems where oil quality is a key issue