B-Lube

PPM oil-in-air monitor

Precise quantification of oil content in airstreams

The contaminating oil can be in the form of liquid, aerosol, vapour, or a combination of them.

The oil removal process usually takes place in a filtration system or in air-oil separators but depending on the serviceability of the filters or the quality of the oil separator, some oil may remain in the airstream.

The presence of oil in airstreams must be banished when medical applications are involved.

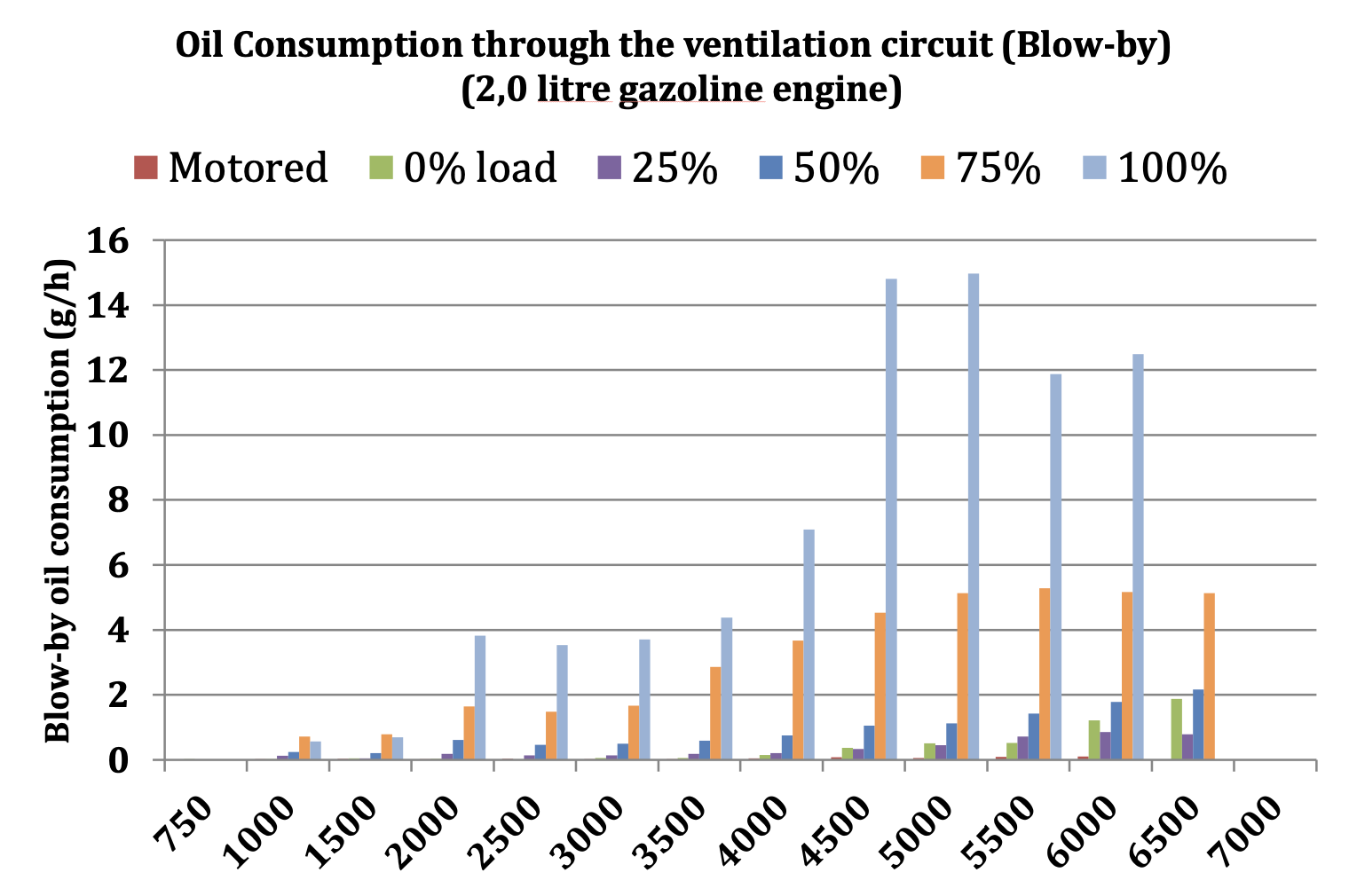

Oil-in-air can also be the cause oil consumption on mechanical systems such as internal combustion engines or compressors.

B-Lube allows precise quantification of oil content in airstreams.

The methodology is dedicated to R&D centers involved with the development of compressors, oil separators and any other system where the presence of oil in airstreams must be banished.

Methodologies for determining the oil content

The weighting method: The internal absolute filter is weighted continuously or periodically to determine the quantity of trapped oil with an accuracy of several grams per hour;

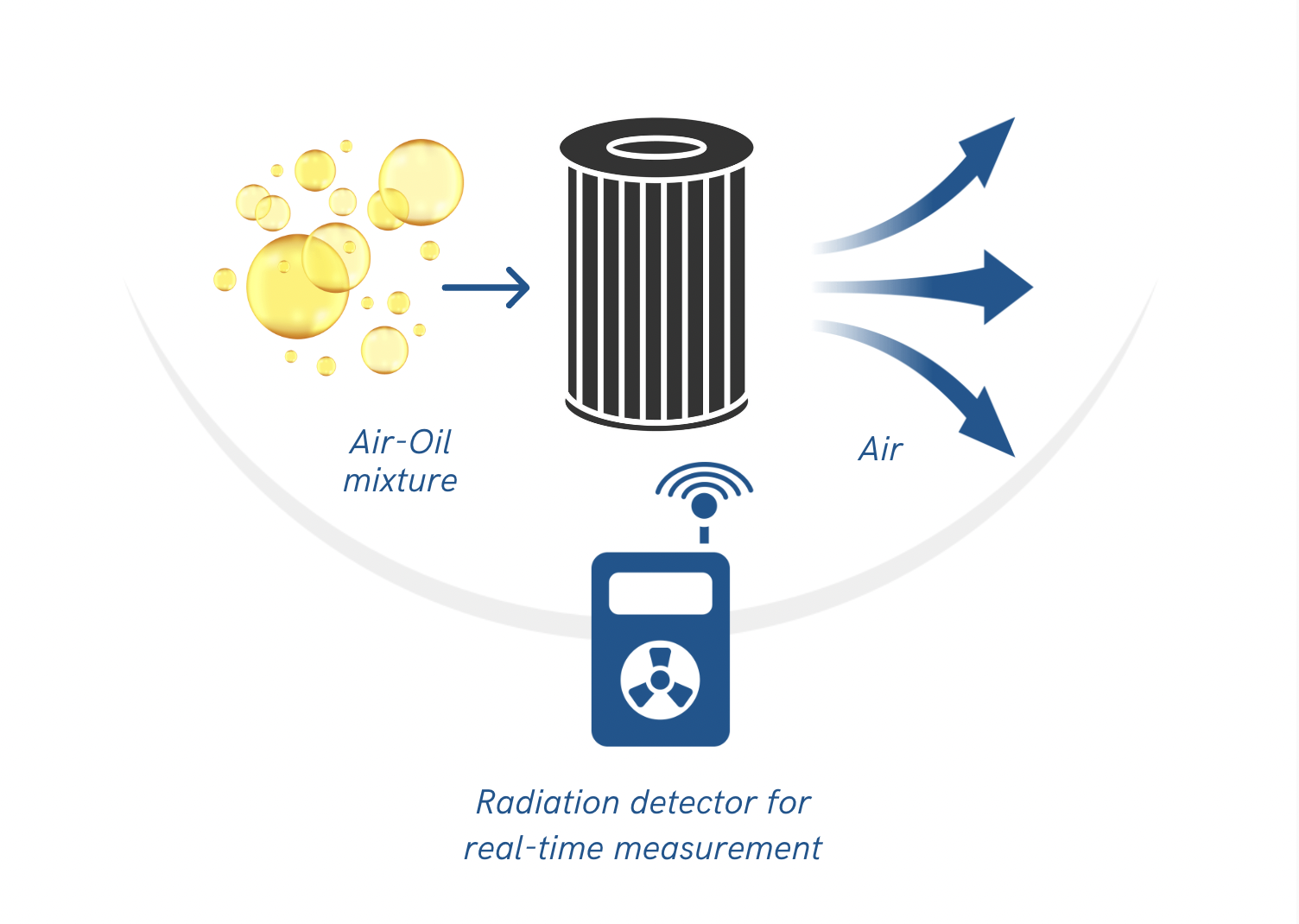

The radiotracer method: it consists in labelling the oil to measure in real-time the level of activity trapped in the absolute filter. It offers a sensitivity in the range of milligrams per hour.

Operating principle

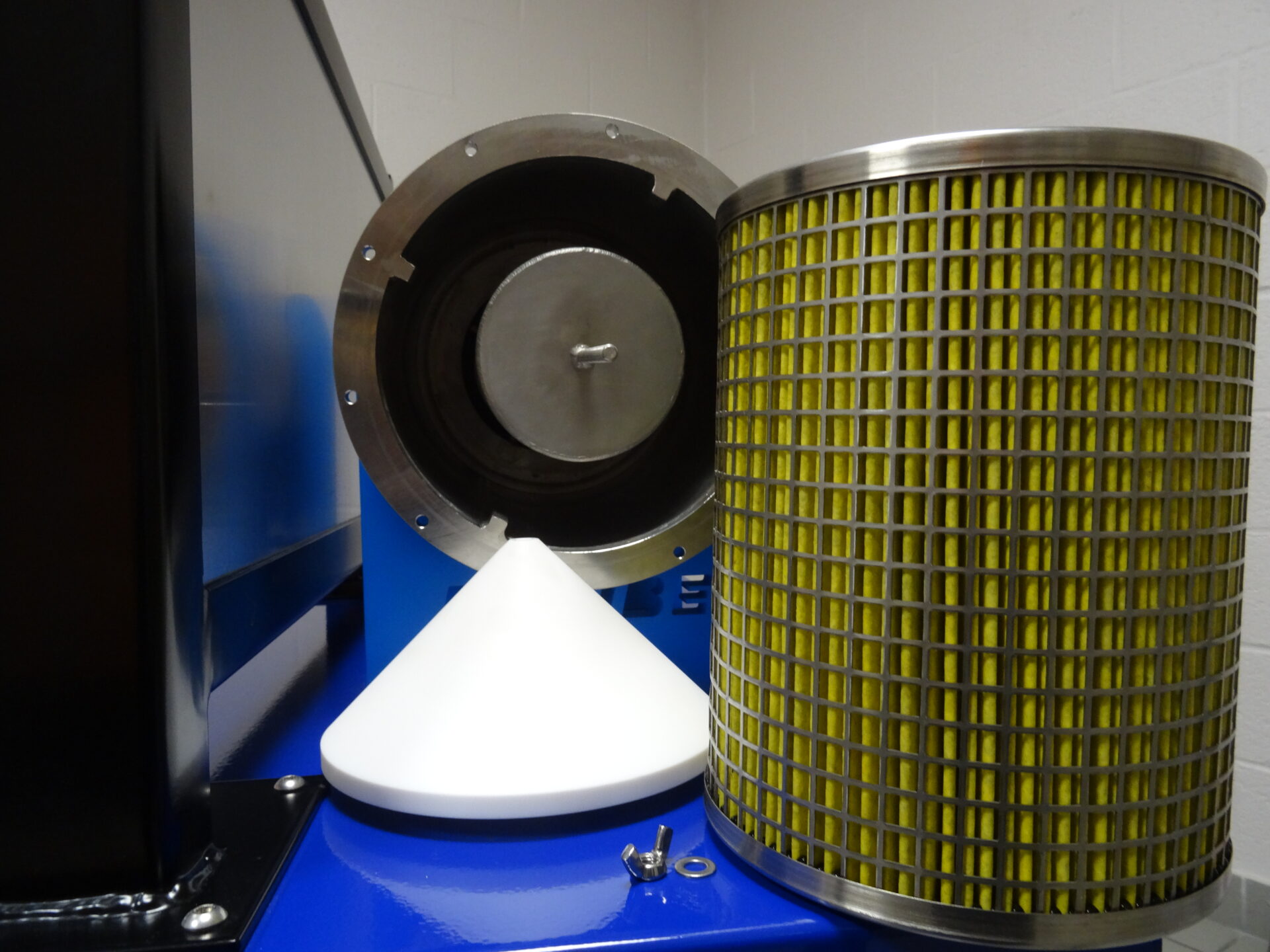

Engine oil is labeled with a radiotracer. This makes it possible to detect very small amounts of oil present in airstreams, in the range of milligrams. The measurement consists of monitoring, in realtime, the amount of oil trapped in an absolute filter. The amplitude of the detected signal is proportional to the quantity of oil trapped by the filter. A dedicated software provides oil consumption results in grams/hour. The methodology is reliable, repeatable and very sensitive.

Advantages

On-line / Real-time results. A precise measurement of oil consumption through the ventilation circuit for one operating condition is typically acquired within 15 to 30 minutes. Analysis of transient phases is also possible by increasing the amount of tracer mixed in the oil, or/and by repeating transient data according to pre-defined sequences.

When applied on I.C. engines, a complete blow-by oil consumption map is performed within 1 day for typical consumption rates in the range of 0,5 to 10 grams/hour. Sensitivity is of ~10 milligram/hour. It can be increased by increasing the dose of radiotracer mixed to the oil.

It allows monitoring the performances of oil mist separator systems in real operating conditions.

Water fraction does not impact measurement results. Water accumulated in the ventilation circuit is NOT taken into account since oil only is labelled with the radiotracer.

Simple and efficient working principle. Performing measurements is simple and intuitive for operators.

Quick commissioning: Efficiency of the measuring chamber is factory calibrated.

The measuring chamber offers negligible pressure losses.

The method can be applied in laboratory, on test beds and on vehicles. Various equipment configurations are available to cover a wide range of applications. A compact system is also available for on-board installation, with local data logger for acquisition during road tests.

Specifications

Real-time measuring system based on the Ge69 radiotracer method

Sensitivity: better than 0.1g with 10 MBq Ge69 (5L oil in the sump)

Accuracy: 3% after 20-30 min. at oil consumption rate of 5 g/h with 10 MBq Ge69 (5L oil in the sump)

BBY flow rate: 1 to 500 l/min with negligible back pressure

Efficiency of absolute filters: 99.9% for BBY flow rates between 0- 500 L/min

Measuring chamber: made of stainless steel

Absolute filter: multi-layer synthetic filters for high temperature operation and desiccation at 120°C

Measuring probe: cylindrical, 10” NaI(Tl)detector with cooling jacket

MCA system: 4096 channel high resolution spectroscopy system

Software: add-on to “C-Lube” software for on-line engine oil consumption equipment

Operating system: Windows 10-11

Analog inputs and outputs: yes, for communication with external control system

Dimensions: 500x500x1000mm (WxLxH)

Weight: 200 kg including lead shield against direct radiation from engine labelled oil

Scope of supply

Measuring chamber with filter and 10” radiation detector with cooling jacket

Integrated electronics with High Voltage Power Supply and 4.096 channel high speed Multi Channel Analyser for NaI detector, Ethernet interface

Support frame cabinet (aluminum) with 50 mm internal lead shield

Scissor lift table on castor-wheels

Dedicated add-on for “C-Lube” software

2-years warranty and free software update