Dedicated

Test Rigs

DSi has acquired a strong expertise in the development, manufacturing and installation of dedicated test tools for engines and lubricants.

Field of Application

Lubricant benchmarking

Friction loss measurement

Wear of valve trains

Controlled conditions

Cokefaction tendencies of oil formulations

Performances

Rotation speed from 0 to 7500 rpm for valvetrains or up to 10 000 rpm

Oil temperature conditioning from 35 to 135°C or up to 250°C

Oil flow regulation down to 0.6 l/min

Coolant temperature conditioning from 35°C to 110°C

Accurate torque measurement up to 100 +/- 0.015 Nm

Standard acquisition up to 100Hz

Fast acquisition up to 30 kHz / 256 points per rotation

Custom made possibilities

Mechanical design according to the system to test

Oil conditions (Temperature, pressure,flow rate,...)

Coolant conditioning

Conditioner dimensions

Combine Test Rigs with TC-Lube

Components tested

Fluid conditioning systems

Turnkey solutions

Cylinder head benches

Development, manufacturing and installation of a turn-key aeration test rig for formula 1 oil tank

Development and manufacturing of oil and water conditioners for test beds with very accurate flow and temperature control (engine test facility)

Development of test rigs for friction losses measurement

Development of test procedures to compare the impact of lubricant formulation and oil aging on engine wear

Development of separate oil conditioning equipment for turbochargers : TC-Lube

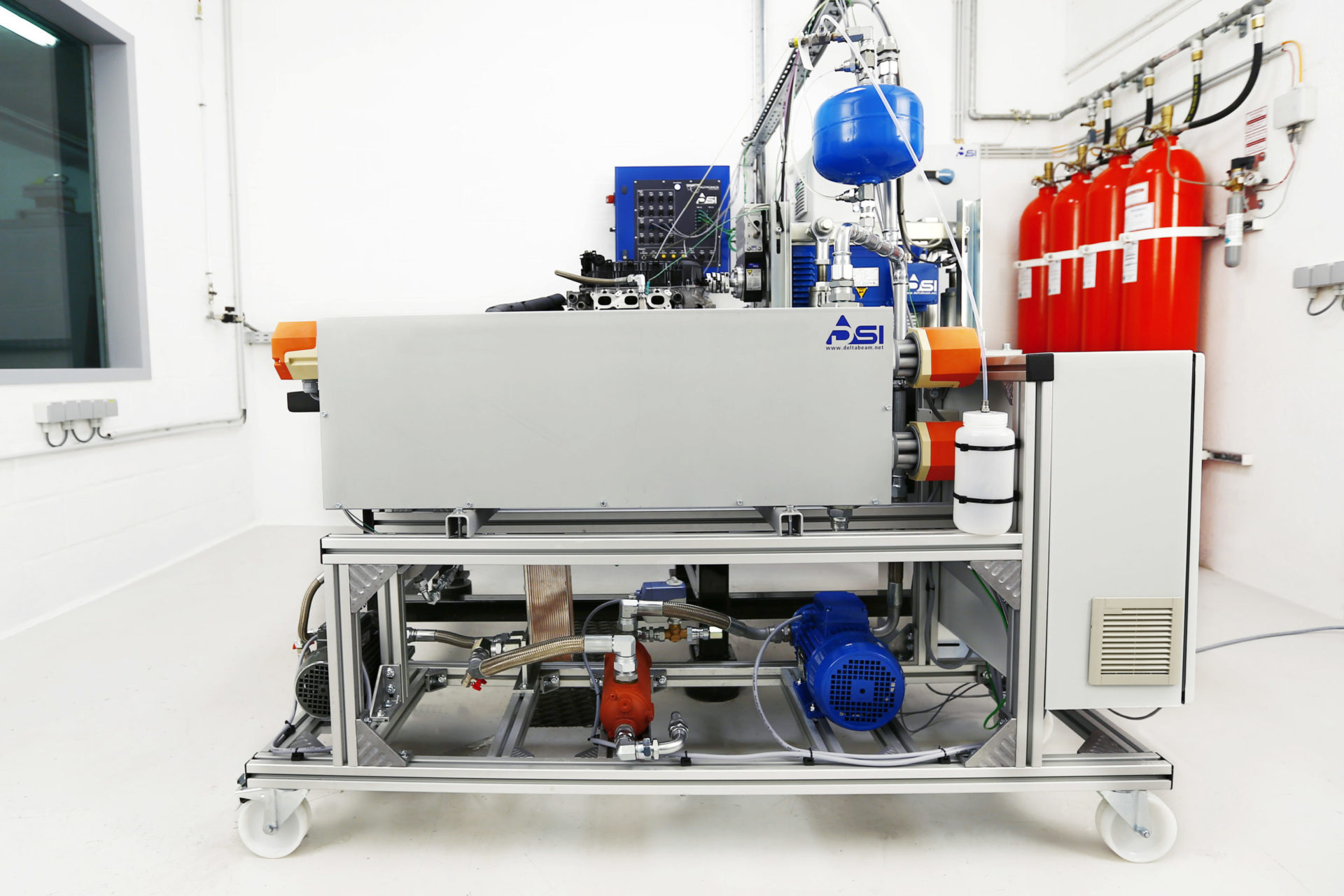

Cylinder-head test rig

For benchmarking oil formulations

Design and manufacturing of cylinder-head support with oil and coolant circulation

Accurate torque measurement

Fast acquisition of 265 points per rotation

Validating oil formulations at different temperatures

Can be combined with TLA/RNT for online wearing of valvetrain components

Can be combined with Air-X for aeration measurement on cylinder-heads

On site measurements