Our services for hydrogen

We are your partner for every step in your H² project

Our services

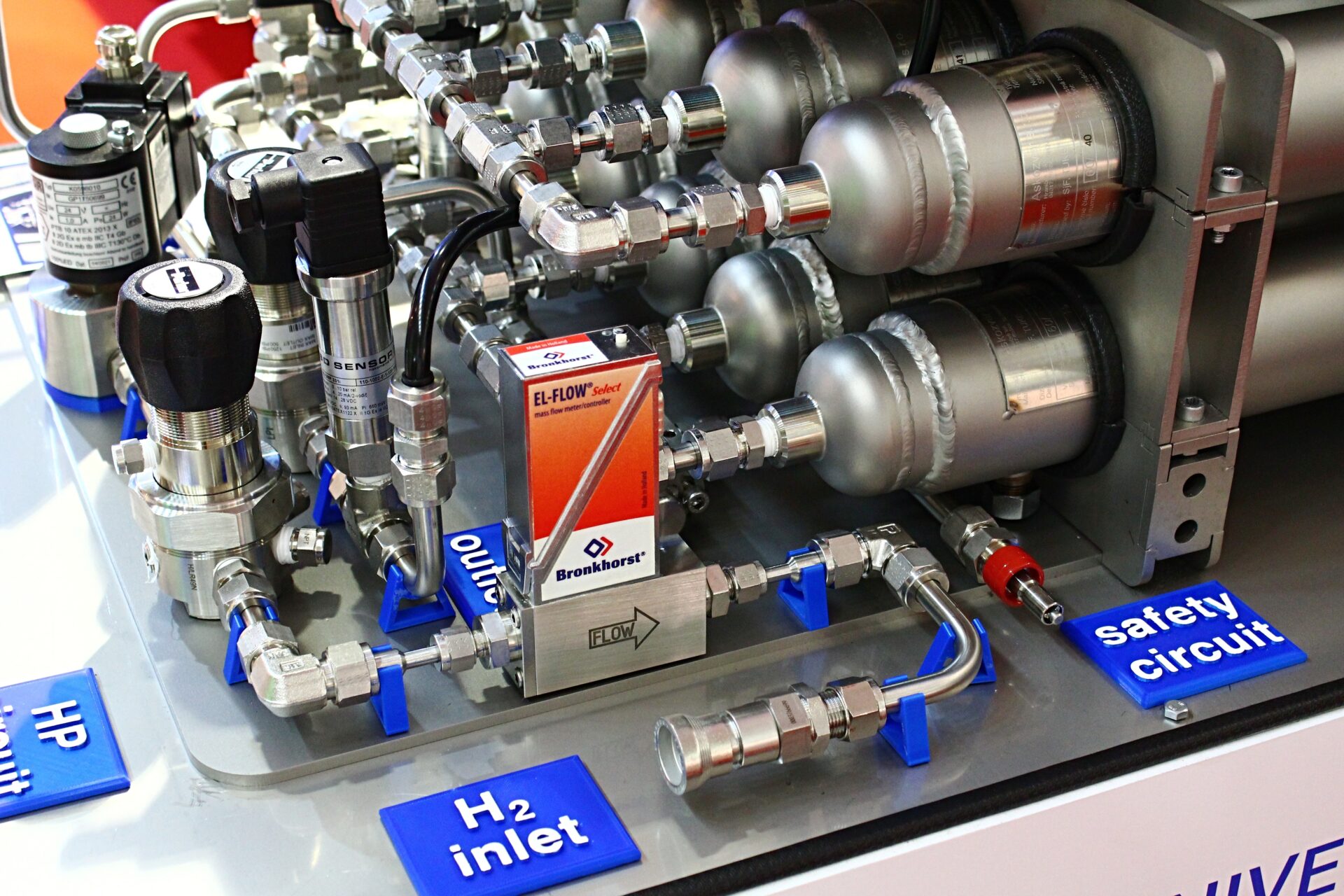

Pre-study: analysis of your existing test cell(s), and risk analysis

Engineering: selection of all components: tanks, piping, valves, pressure regulation, flowmeters, etc.

Safety: selection and implementation of H² detection probes; installation and programming of a local safety PLC

Upgrade of existing equipment for H2 compatibility (ventilation system, electrical cabinets, and other hardware)

Supply of hardware and in-situ installation services

Validation and assistance for accreditation with local authorities

Our proposals focus on finding the most cost-effective solution for our customers

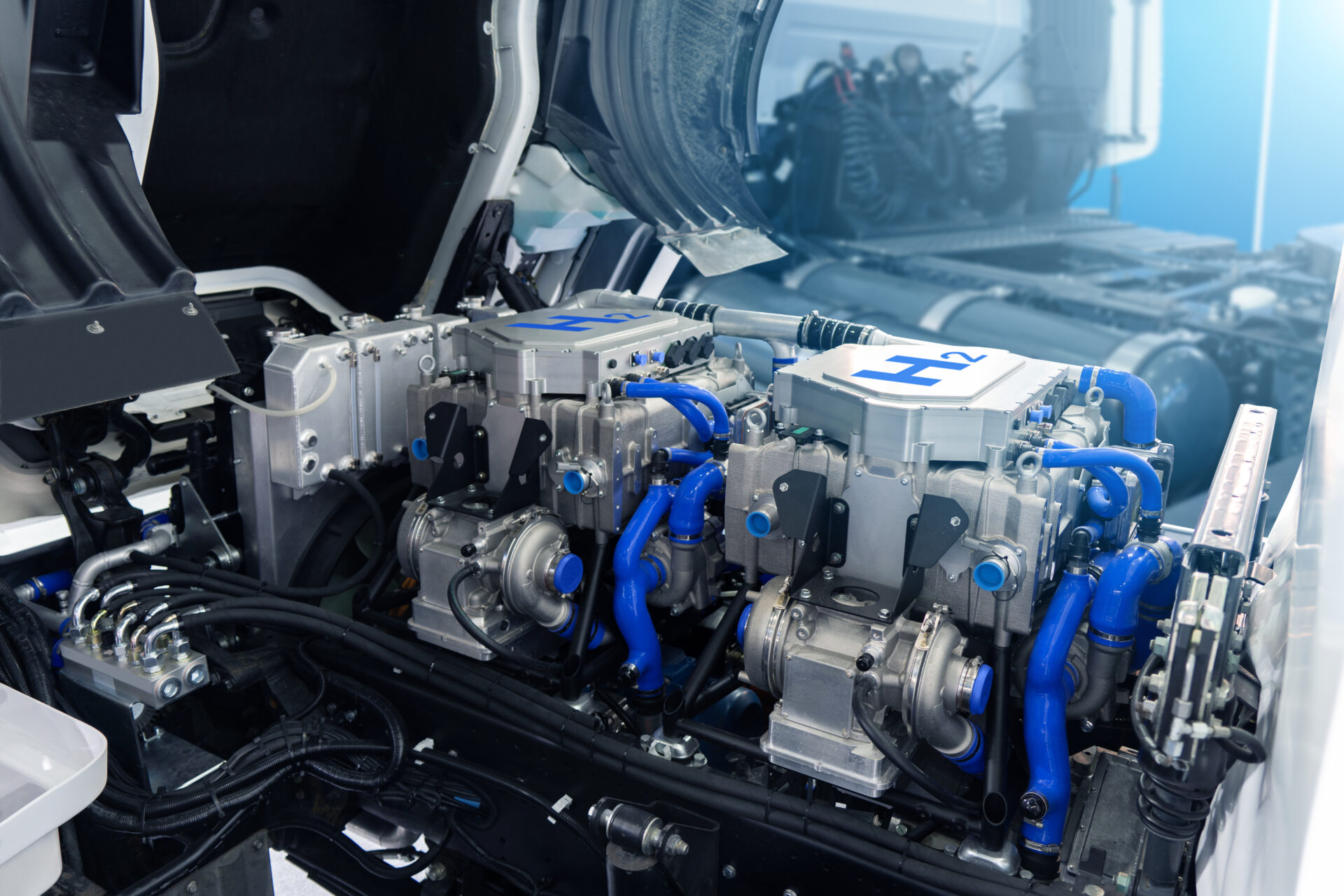

DSi is involved in the conversion of high performances racing engines to Hydrogen

Dsi tools for Hydrogen-Fueled Engine

Real-time oil consumption measurement with C-Lube: H2 combustion happens closer to the cylinder wall compared to diesel, inducing higher temperatures. New oil formulations are under development and DSi will assist you in comparing oil consumption rates

Wear is another issue due to the potential corrosion due to the presence of water in the combustion chambers. The dynamic behavior of exhaust valves is also of interest/concern, it can be measured in real-time with our TLA / RNT technology.

Combustion of hydrogen leads to an increased presence of water in the exhaust and in the oil separator (blowby) systems, leading also to oil dilution. DSi offers equipment for real-time dilution measurement (D-Lube) and smart probes for real-time water detection (sensibility of 50 ppm)

Additional test tools for IC hydrogen engines

Real-time oil consumption measurement with C-Lube: H2 combustion happens closer to the cylinder wall compared to diesel, inducing higher temperatures. New oil formulations are under development and DSi will assist you in comparing oil consumption rates

Wear is another issue due to the potential corrosion due to the presence of water in the combustion chambers. The dynamic behavior of exhaust valves is also of interest/concern, it can be measured in real-time with our TLA / RNT technology

Combustion of hydrogen leads to an increased presence of water in the exhaust and in the oil separator (blowby) systems, leading also to oil dilution. DSi offers equipment for real-time dilution measurement (D-Lube) and smart probes for real-time water detection (sensibility of 50 ppm)

Detergent oil additives are sometimes switched from Ca to Mg to reduce pre-ignition which can lead to other issues including wear and catalyst poisoning

Optimization of oil mist separator design: as blow-by gases will contain H2, DSi can assist you in developing active blow-by systems that can handle high blow-by flow rates. Our equipment B-Lube measures in real-time the flow of oil and water in the PCV system, and the efficiency measurement of blow-by separator)

Main concerns in a H2 conversion project

A pre-study phase is necessary to determine the compatibility of existing equipment and specify the new hardware

SAFETY issues are fundamental, hydrogen is light & risk of explosion exists above 4% hydrogen concentration in air

In many cases, adaptations of existing equipment allow compliance with H² safety requirements

No need to SYSTEMATICALLY purchase ATEX hardware!

Implementation of hydrogen supply

In-house storage capacity with compressor system when high capacity is required (heavy-duty engines…)

H2 supply by trailers is recommended when limited capacity is needed

Our engineering services focus on finding the most cost-effective solution for our customers

H² distribution system in engine test cell

Dedicated hardware with accurate pressure and flow controls

Redundant Safety interlocks, from tank to engine

Piping flushing system with inert gaz

Installation of efficient venting systems with embedded leak detectors

H2 project in Belgium

560 solar panels already installed at our premises

190 MWh production per year (2023)

Conversion of 1 ICE test bench to H²

Electrolyser project under study

Safety above all

Installation of taylor-made venting systems to adapt existing hardware

Adaptation of engine inlet and exhaust lines

Dual function gas detectors installed at critical zones inside the test cells

Independent Safety PLC

Installation of explosion-proof walls