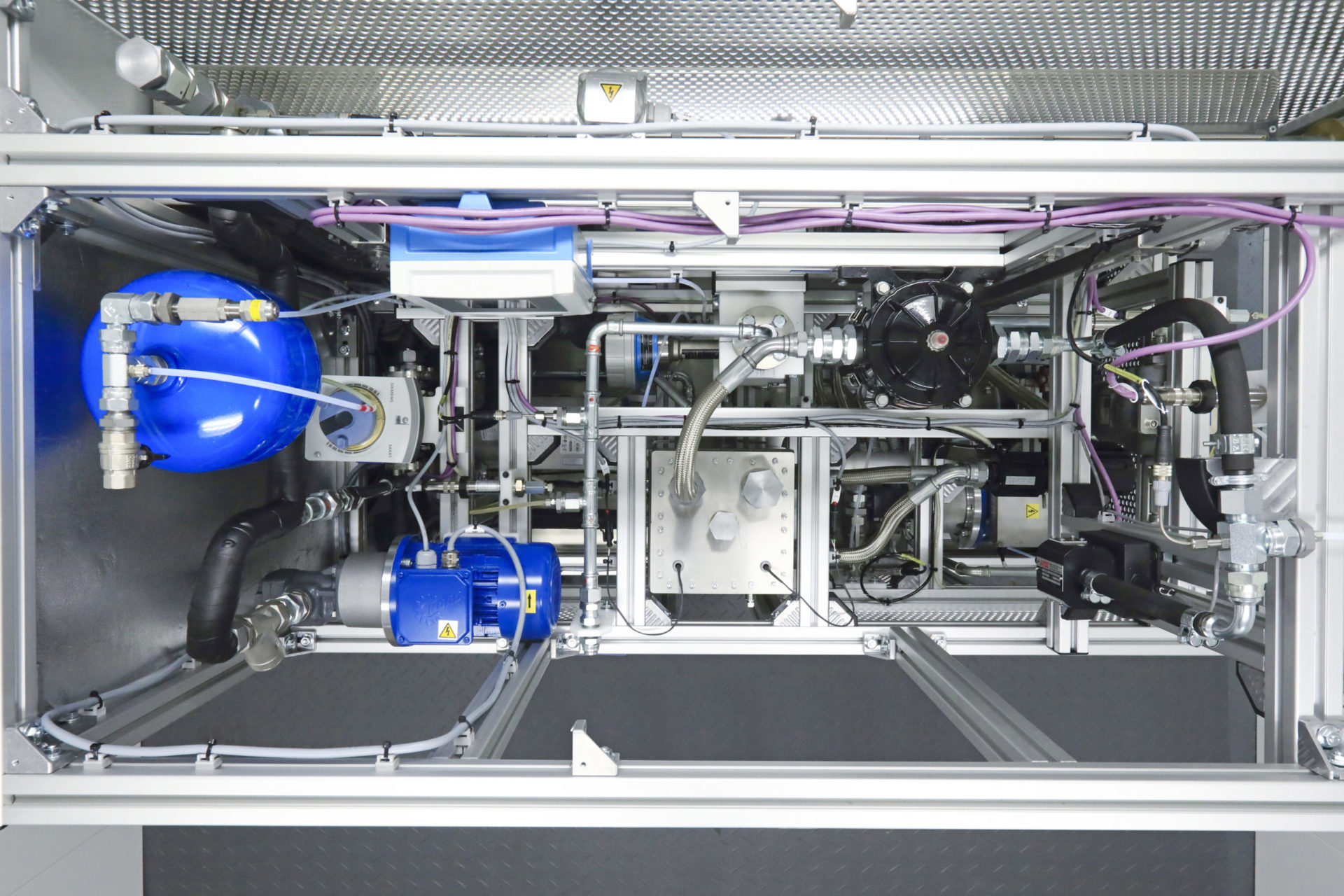

Fluid Conditioning Systems

Design and development of Taylor-made Oil and Water conditioning systems

A few examples of recent developments:

Oil and water conditioning systems for test rigs and test benches, from simple heating/cooling units to complex equipment to supply Formula 1 engines and Jet engines.

AIR-MIX is an oil conditioning unit where oil temperature, flow and aeration rate are accurately controlled via a PLC. It is used to generate aerated oil and supply mechanical systems and check the operating limits (valvetrains, oil pumps, a gearbox or a complete engine).

FLUCOIL is an oil conditioning unit designed to accelerate oil aging. It combines high temperature (hot spots), fast oxidation with air or oxygen, fuel, water and wear debris injection systems to simulate real conditions in mechanical systems such as gearboxes, I.C. engines, etc. It can also be used to test and determine the response of smart probes for real-time measurement of oil conditions (viscosity, dielectric constant, water content, wear debris content, etc.)

TC-LUBE (Turbo-Charger Lubrication) for independent lubrication of turbochargers. It allows testing engines with independent oil supply of turbochargers to optimize oil flow and determine the operating limits. It can be combined with radiotracer techniques to measure wear and oil consumption of turbochargers, independently of the rest of the engine.

Specificities

Our oil/water conditioning units are designed according to your needs, and 100% built and tested at our facility

They can be equipped with a local PLC. The operating setpoints can be locally programmed or sent from an external source (i.e. test bed control system) through analogic or digital (CAN) communication.

Lubrication limits of various oil formulations are easily investigated and compared in terms of oil quality, oil aging, behaviour when air, water, wear debris or soot are present in the oil.

Optional scavenge capacities with vacuum regulation are available for aeronautic and racing applications

Applications

Powertrains

Gear boxes

Turbo chargers

Racing hybrid units

Jet engine subsystems

Development of Smart Probes for Lubricants

Industrial Machinery

Size & Dimensions

Operating ranges (pressure, flow rate, temperature, air content, ...)

Heating / Cooling features

Remote control / Interface / Communication protocol

Shipment and commissioning anywhere in the world

CE or UL certified