TLA/RNT

Real-time wear monitoring

TLA/RNT method allows performing real-time wear measurements on mechanical systems.

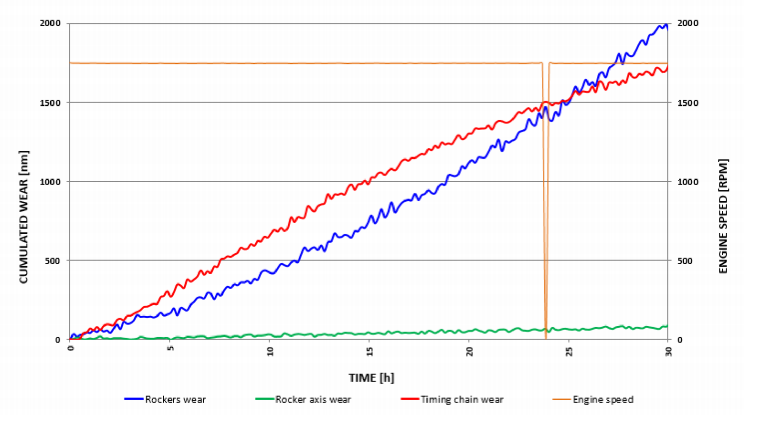

TLA-RNT methodology allows continuous wear measurements on running mechanical systems such as powertrains, transmissions and hydraulic systems. It offers wear results with very high sensitivity in the range of one nanometer per hour (1 nanometer = 1/1000 of a micron).

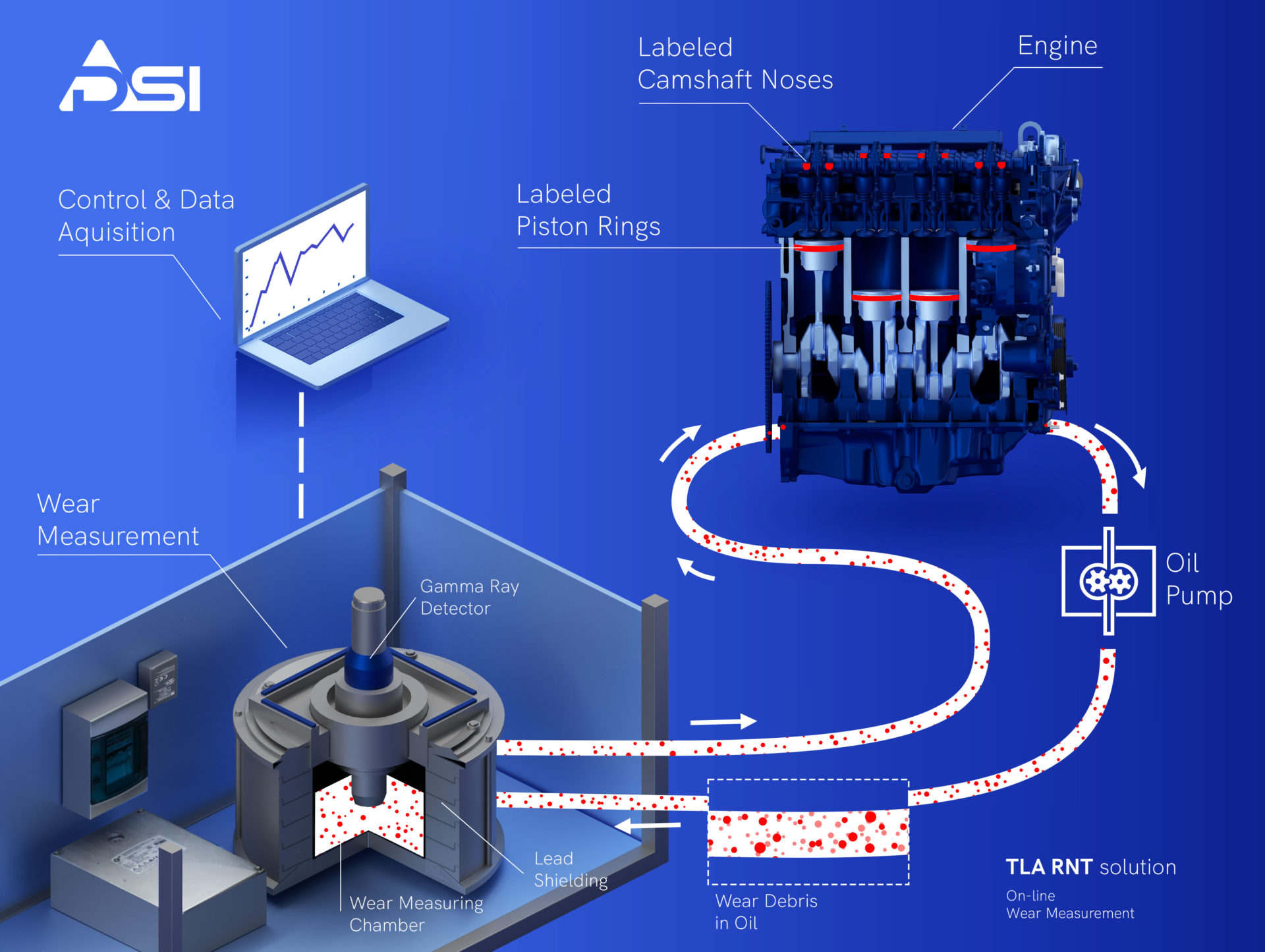

TLA-RNT equipment operating principle is based on the use of the Thin Layer Activation (TLA) technology (also called RNT for Radio Nuclide Technique), which is based on the production of radiotracers on the surface of critical wear parts. The extreme sensitivity of the methodology and its accuracy allows shortening significantly test durations compared to conventional wear measurement procedures.

Our TLA-RNT solution is easily adapted to any mechanical system, from small tribology test rigs to heavy duty engines or transmissions. The equipment offers real-time results and short response times in the range of seconds.

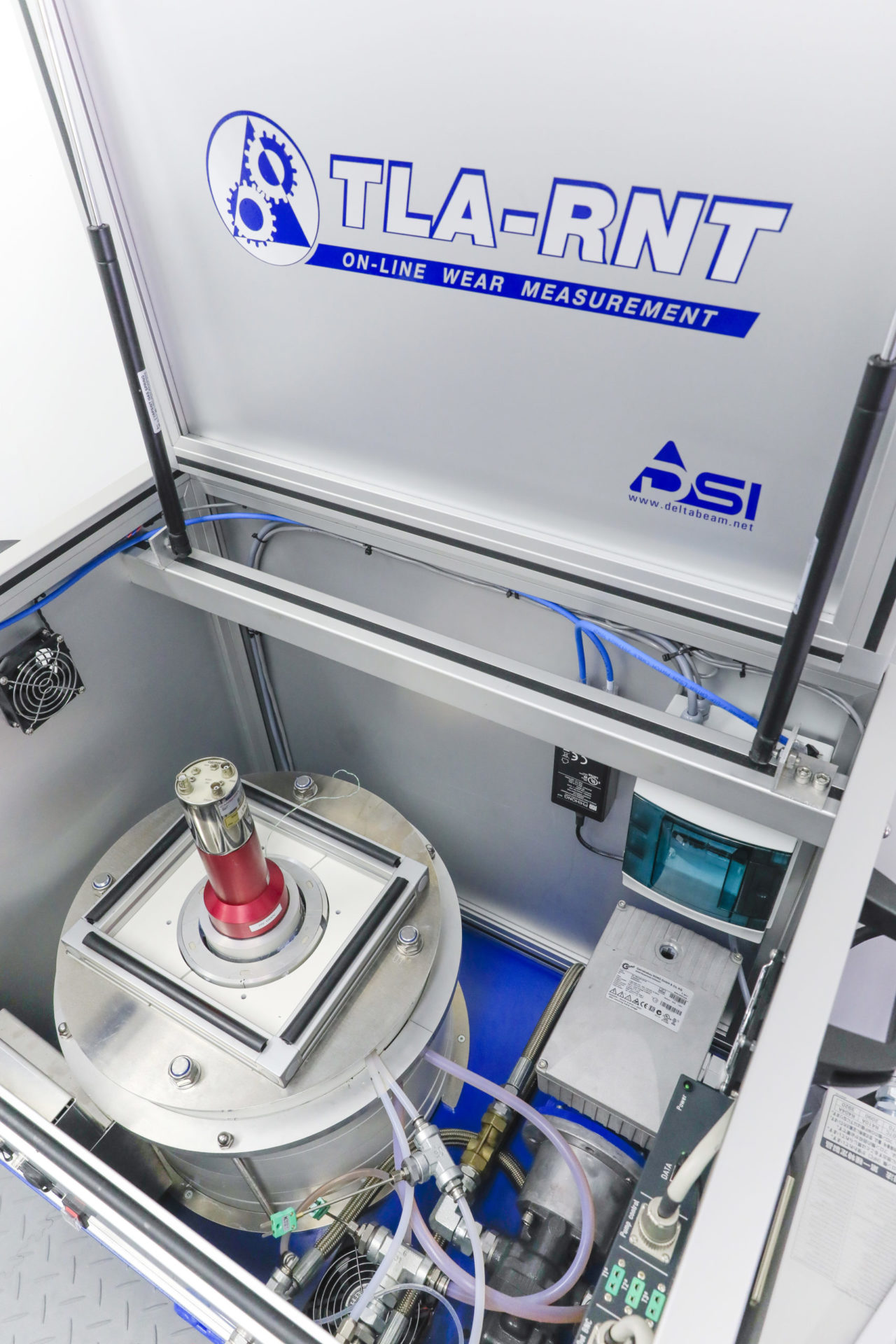

The heart of our TLA equipment is a measuring chamber where oil is circulated. A very sensitive probe detects the signal emitted by wear debris that accumulates in the lubricant (or in the oil filter) when wear occurs. A high-resolution MCA (Multi Channel Analysis) is used to differentiate the signal emitted by labelled parts undergoing wear (up to 4 parts made of different materials), controlled by a user-friendly software that offers real-time wear results.

TLA/RNT methodology is also convenient for real-time wear measurement on very hard coatings (such as DLCs), for which very low wear rates are usually involved as well as very low thicknesses in the range of several microns.

Operating principle

The TLA (Thin Layer Activation) / RNT (Radio Nuclide Technique) method applies to the development of mechanical systems and lubricants. It allows performing real-time wear measurements without dismantling parts (i.e. gears, camshafts, cylinder sleeves, piston rings, valves & seats, bearings, turbocharger bearings, etc.).

High resolution spectroscopy system

TLA-RNT equipment uses a Multi-Channel Analyzer (MCA) that allows differentiating gamma-rays coming from different isotopes. The equipment allows monitoring simultaneously wear debris coming from 4 different parts installed in a mechanical system.

Combine it with an Air-Mix for specific engine conditions

Components tested

Camshafts

Cylinder sleeves

Piston rings

Valves & seats

Turbocharger bearings

Timing chain

Conrod bearings

Gearboxes

Software

TLA-RNT equipment includes a user-friendly software (B-Wear) that performs a multitude of control and analysis functions to effect TLA/RNT experiments.

It operates under Windows® and performs automatic saving of raw data on hard disk during the measurements and re-analysis of raw data with new parameters.

I/O are available to communicate with the control system of most R&D test rigs / test benches.

B-Wear TLA equipment is also equipped with its own data acquisition system and, as an option, additional analog/digital inputs are available for acquiring external signals issuing from the test rig itself.

Another feature of B-Wear is the possibility to display wear rates in real-time. A special function allows performing linear fits in wear data to calculate the rate and the standard deviation.