Air-X for

Oil aeration monitoring

Air-X strenghts

Based on X-ray transmission: range from 0% to 100% gas content

Continuous oil sampling, at regulated flow (selectable)

Allows measuring both dissolved and non-dissolved fractions

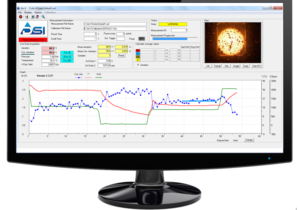

Real-time results with an accuracy of 0.1% in term of gas content

Easy absolute calibration

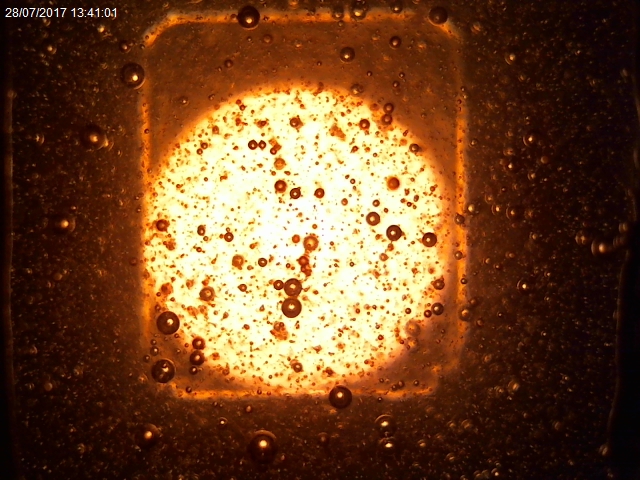

Visualisation of oil flow in the measuring chamber (video signal)

On-board model available

User-friendly and quickly set up

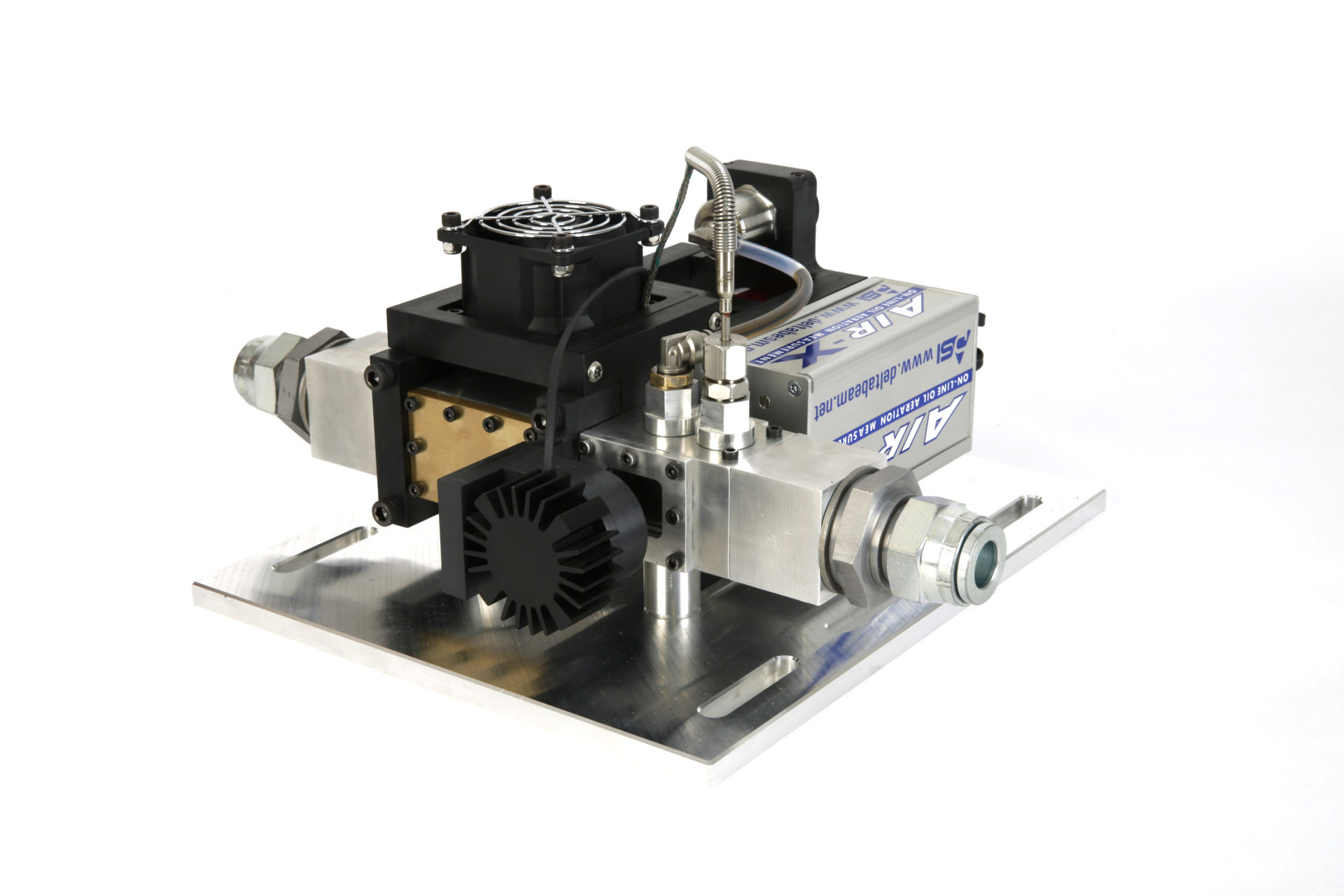

Air-X Compact

Air-X has been designed for on-line monitoring of oil aeration in a running mechanical system (engine, oil pump, gear box, hydraulic circuit, etc.). The operating principle is based on an accurate density measurement using X-ray transmission combined to X-ray spectrometry analysis. An oil sample coming from the mechanical system is circulated continuously into a measuring chamber where the density measurement is performed.

Particularly suitable for stationary dyno, tilt rig, on-board and dry sump applications, it is a lightweight and ruggedized compact measuring chamber to be fitted close to the mechanical system. The electronics is deported to reduce the size at its best. It does not have an internal pump to circulate the lubricant so the unit has to be connected adequately to create a lubricant flow within the chamber.

DSI Expertise

DSI team has acquired a strong expertise in assisting our customers to understand and solve aeration problems. Here are the features of our services.

Moving

Service measurement with Air-X equipment, at your company

Training

Training on the aeration process (theoretical and practice)

Renting

Service measurement at DSi including rent of engine test tools

Designing

Design and manufacturing of dedicated test rigs for supply of aerated oil

Solving

Solving aeration problems by adapting the oil circuit and lubricant properties

Developing

Development of special configuration in the hydraulic and mechanical industries

They trust us since years

Air-X is now commercialized for more than 17 years and has become a reference tool in the industry for Oil Aeration Monitoring with several references worldwide (whom engines manufacturers and lubricants manufacturers). They all agree that working with DSI is the right way to accelerate their R&D programs. What about you ?