Oil Dilution Measurement for I.C. Engine & Hybrid Powertrain during Cold Start

1. Customer application

The customer wants to measure the oil dilution by water due to hybrid engines cold starts. The operating principle of a hybrid engine is to turn on the internal combustion engine to relieve the electric engine when the power demand is high (and use the hybrid engine at maximum capacity), to charge the batteries or to take over when the batteries are totally discharged. The high temperature of the combustion chamber combined with the low temperature of the engine at start-up creates condensation which generates dilution.

2. Customer needs

The customer needs to measure dilution in the I.C. engine in real time.

3. Customer goal

The customer must decide whether the dilution rate achieved is acceptable or whether to take corrective actions to solve the problem.

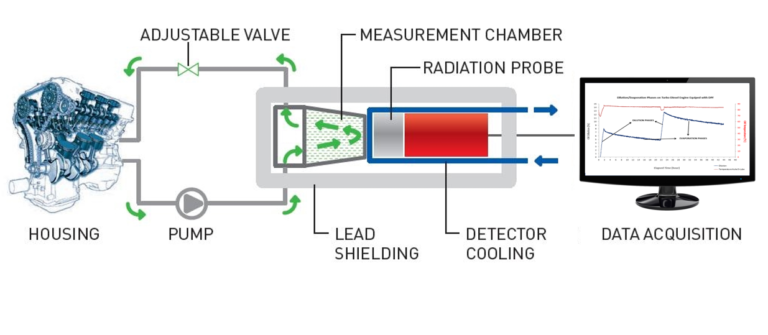

4. DSi solution

Our customers use the D-Lube equipment to measure dilution on their I.C. engine. A simple connection between the crankcase and the D-Lube allows measuring the dilution in real time. Mixed with our tracer, the oil circulates in our D-Lube that continuously measures the dilution rate. The dilution rate is calculated automatically by the software on the basis of a concentration modification of the radiotracer in the oil. The results are provided to the operator every minute and the equipment reaches a sensitivity of 0.05% per hour. The D-Lube results can be used directly without post-processing. A campaign carried out on an engine generally takes around 4 hours. Some users makes longer campaigns to validate their corrective actions. Our equipment can be used both in standard test cell, climatic cell and on board. Usually, users take a 1 or 2 day training with a DSi engineer so that they are able to manipulate D-Lube on their own.

More information on :

D-Lube page

infos@deltabeam.net